“I AM STILL LEARNING”

Last week, I attended the Materialise 3D Printing conference at RMIT with MCAM and AMAERO staff. I also went to the Parallels – Journeys into Contemporary Making conference at the National Gallery of Victoria. It was great to hear what’s new in 3D Printing and different views on the changing world of craft and design.

There have been a lot of talks about the wonderful new manufacturing method, namely 3D printing. But it seemed there was an assumption that everyone can use 3D modelling software programs to create models for 3D printing; and another assumption is that any form or structure can be printed with a 3D printer. In fact, there are so much to learn before one can fully use this wonder technology.

During the Materialise conference I learned that the current trend in 3D printing techniques is lattice structures, which involve repetitive patterns of cell shapes or types. It’s said that apart from being unique to 3D printing, lattice structures are much more flexible, versatile and much lighter but can be stiffer than solid structures. Without a doubt, soon there will be new design tools available for us to create lattice structures for 3D printing.

If we are willing to use complex and unfamiliar tools and not to restrict ourselves to the usual applications of the technology, we will discover not just possibilities and limitations of the new tools but also the conditions and consciousness of our changing world.

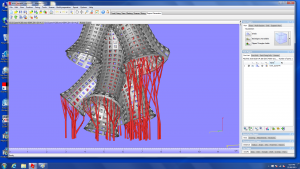

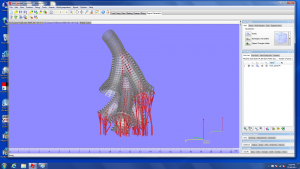

For now, I am willing to train with the software used at MCAM/AMAERO that is MAGICS. This software is used to check, fix or alter 3D models before they are printed. Timely, AMAERO has just acquired a new copy of MAGICS which allows me to manually create tree supports for my 3D models. I AM STIIL LEARNING IT!

(I AM STILL LEARNING, or ANCORA IMPARO, is in fact Monash University’s motto! )

While creating tree supports in MAGICS is very slow and laborious, this task can be done with just a few clicks in FORM1 3D printer’ s Preform software. However, since the tree supports are added manually in MAGICS, we can design the shape and position of the ‘trees’. Preform’s tree supports are simple straight columns with short branches, and are generated by the software based on the angle and position of the overhangs (which we can’t really change).

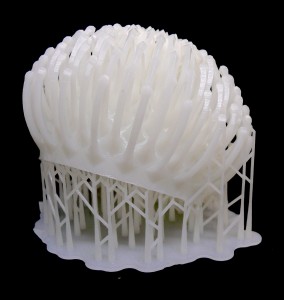

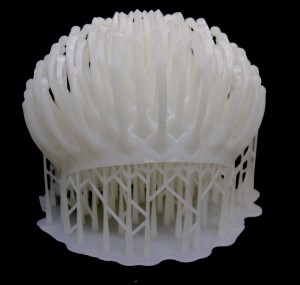

Below is a photo of my new 3D prints – Both are 7cm high; the print on the left was printed with a MakerBot printer without supports. The grey object on the right was built with a FORM1 printer; tree supports were needed to support the slightly tilted model(to ensure that the base of the print will be clean and perfect when removed from the resin tray).

I will print a few more versions with different materials (plaster, metal and different resins) next week.

There are so much to learn.

I AM STILL LEARNING!

Today I reprint one of my old 3D models using liquid resin and tree supports. The print is quite heavy due to the additional weight of the supports. I will create the 3D trees myself and reprint this ‘waratah’ model to see how much material I can save.

I am still waiting to have this model printed with plaster powder and colours.